AMS

The order management system for heat treatment

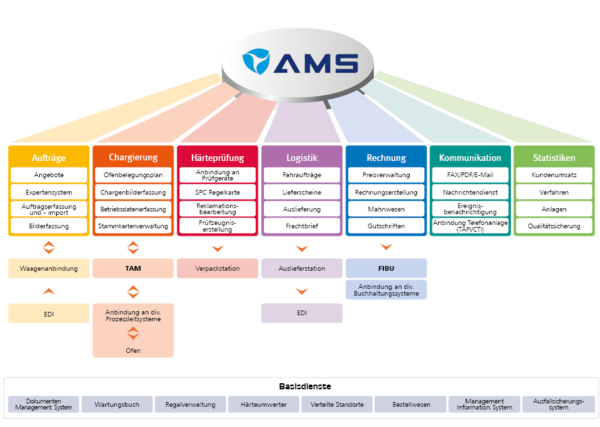

The order management system from ttc informatik GmbH is a modern software solution specially tailored to the needs of contract manufacturers in heat treatment. Highly qualified software developers and experienced industry professionals collaborated to ensure that the system solution could optimally cover all operating areas – from pricing calculation and offer preparation to hardness and metallographic testing, to automated invoicing.

What’s more, with the help of the technical order management system TAM, we combine commercial and administrative areas of order processing with the technical level of system and control technology via the prosys/2 process control system. Technical order management in AMS reflects the basic system component TAM. This unique integration, the modular structure of the programs and the expansion option allows us to flexibly design seamless order, deadline and process management even for small companies. In addition, electricity and gas quantities can be transmitted on a system or batch-specific basis to calculate consumption and profitability.

![[Translate to English:]](/fileadmin/_processed_/d/8/csm_banner-produkte-protop-erp_7fd5a6fc6a.jpg)