The Demig DE-CP 324-01 series

Flexible & Communicative

The process controllers in the DE-CP 32X-01 series are the exciting successors to the successful DE-VX 4310 series! The new generation of controllers has been developed on a modular basis in order to offer a practical solution for every requirement. With the option of separating the ECB bus from the process controller, the installation can be realized in a variety of ways and can therefore be put together specifically for the customer's requirements. And the best thing about it?

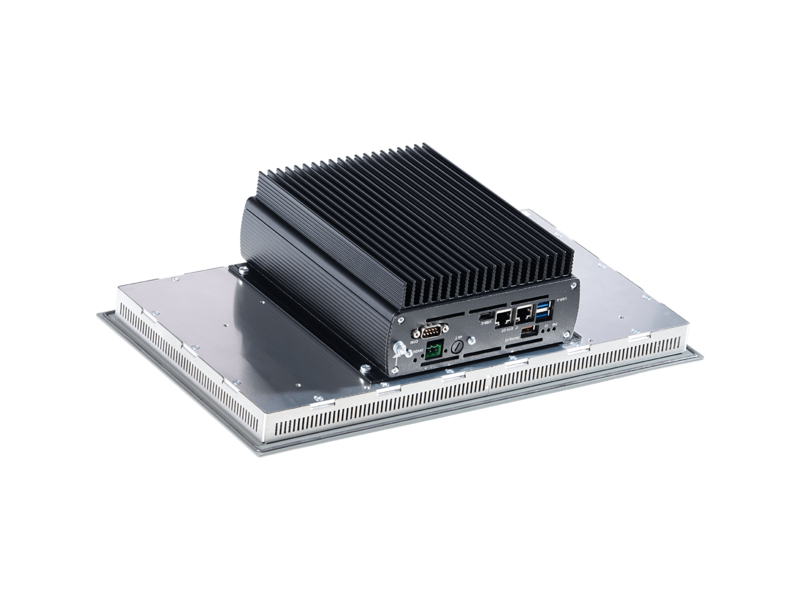

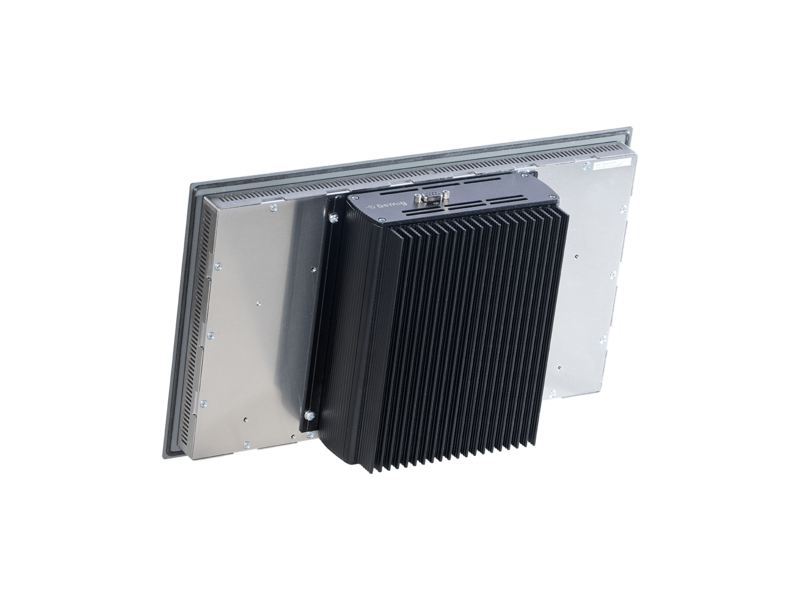

Due to its small size, the DE-CP 324-01 can be easily accommodated! Thanks to the innovative cooling concept, the operating temperature has been significantly reduced! In addition, the system is protected by an integrated UPS, which ensures a controlled shutdown in the event of a power failure.

The integrated ProfiNet module can be used to establish connections to ProfiBus-compatible hardware (master or slave possible)!

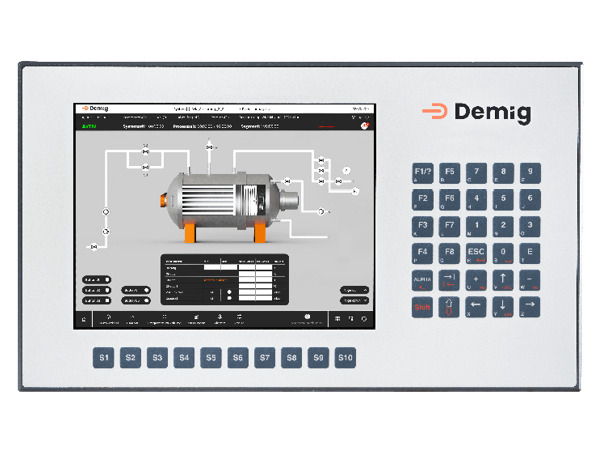

The user interface provides the user with a clear and intuitive visualization and operation of the processes on a 10-inch display with membrane keypad.

The system is driven by a processor that can also display complex visualizations smoothly.

The sequence programs are programmed using preconfigured process phases! The operator is automatically guided to the necessary input of variable data. Phase-dependent basic settings such as monitoring and safety functions are already stored in the system configuration.

Your advantages at a glance

Functional description

Technical data

Accessories

Additional modules

Additional modules:

Online diffusion

(also activates the diffusion simulation in prosys/2)

Iron + carbon results in steel. At temperatures between 911°C and 1392°C, the lattice changes from body-centered cubic to face-centered cubic. Above this temperature, the lattice is again body-centered cubic, but the spacing is greater compared to temperatures below 911°C.

Carburization is used because mixing is not possible. Iron evaporates before carbon becomes liquid, hence the carburization process. The carbon diffuses into the still solid iron at high temperatures. This should happen without oxygen, so inert gases are used to prevent this.

Nitriding index calculation

This is a process for surface hardening of steel and other ferrous materials in which nitrogen is enriched in the metal surface.

Nitrocarburizing is a combination of nitriding and carburizing (i.e. carbon enrichment). The workpiece is exposed to ammonia in a furnace at temperatures of approx. 500°C to 600°C (in nitrocarburizing also with an additional gas containing carbon, e.g. carbon monoxide, carbon dioxide, propane, etc.). The ammonia or the additional gas partially splits on the surface of the workpiece; the resulting atomic nitrogen (or carbon) is embedded in the workpiece and forms a so-called hardening layer. The hydrogen released during nitriding escapes from the furnace together with the unsplit ammonia and is flared off.

Direct coupling Lambda sensor

A lambda sensor is a technical component for heating systems that measures the residual oxygen content of hot exhaust gases. This value can be used to create an optimum mixture of combustion air and flue gases in the combustion chamber, which leads to optimum combustion and reduces the formation of emissions.

Dimensions