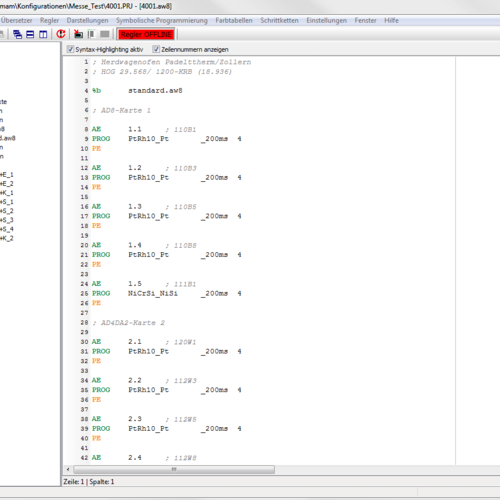

Configuring inputs and outputs

The input wiring for the analogue and digital input cards contained in the process controllers can be selected and combined as needed. The functions of the inputs and outputs are also defined in the configuration. Configuration is completed by programming in a programming language similar to AWL.

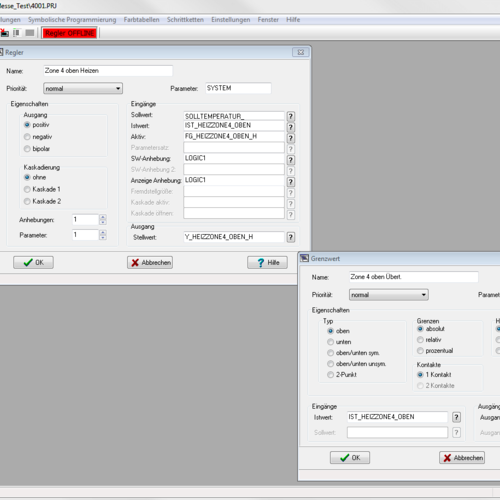

Block configuration

Control loops are structured via a simple symbolic configuration. The control loop blocks available for selection have ready-made interfaces to communicate with the integrated PLC. By creating so-called “associated systems”, it is possible to use process programs later on for multiple systems of the same kind with minimal configuration work required. Integrated control functions are used for troubleshooting and optimisation.

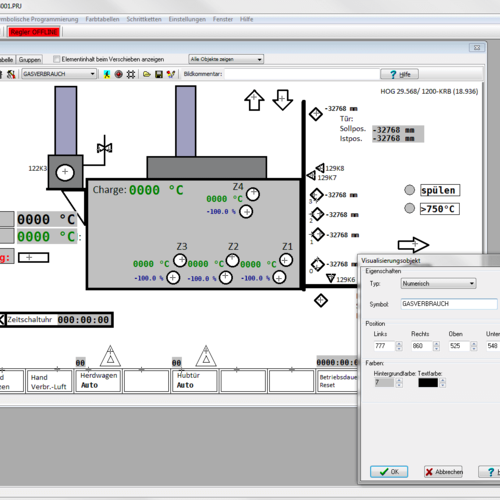

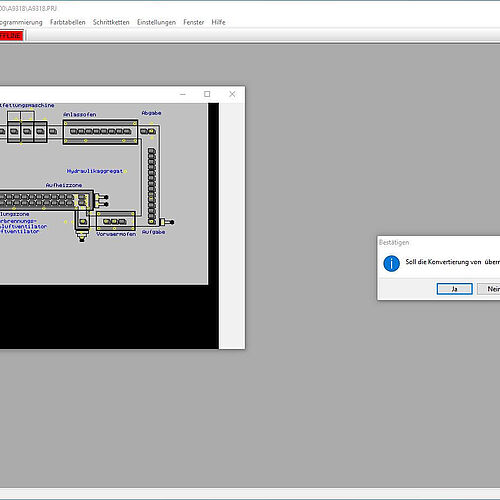

System visualisation

To better monitor processes, custom displays can be prepared on the control system, such as line diagrams or trend displays. Process and system diagrams, into which numerical or trend displays, signal lamps or coloured markings can be integrated, are used to display the current process status. In addition to a dialogue-supported configuration of these visualisation elements, the elements can also be edited in a list in table form.

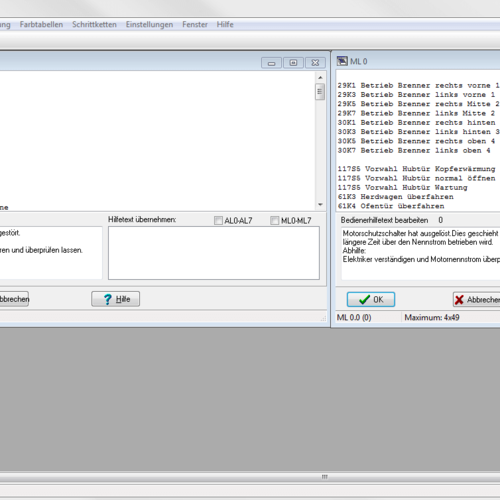

Alarm and notification system

Short error messages and alarms can be configured for display in the process system; help texts can also be generated to support the system operator in reacting to the current situation. Corresponding links in the PLC also allow for automatic reaction by the control system.

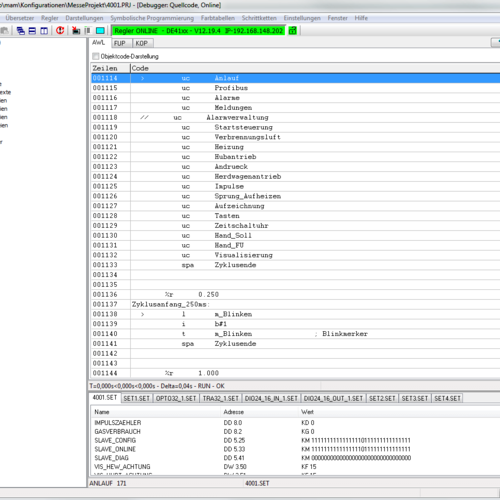

Control via integrated PLC

The internal PLC can carry out all functions of modern programmable controllers. A series of basic commands compatible with the S5© and S7© is available. An expanded command set is available for more specialised problems. Programming is carried out in the familiar AWL structure. An online debugger is available for controlling, which allows the created controller to be tested via object code display and variable monitoring. To provide a better overview, up to eight sets of monitored variables can be displayed; the user can then switch between them easily by clicking on them.

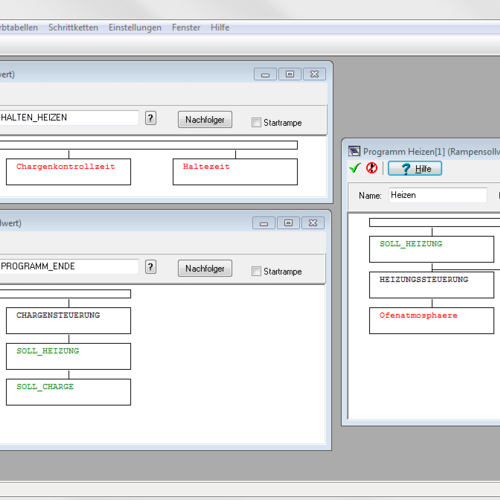

Process-oriented programming

By configuring process phases, the system builder can provide their specialised expertise to the operator, thereby offering a control and regulation system individually optimised to the system. All necessary control functions are carried out automatically in the background. Non-plausible entries by the operator are prevented by the decision-making tree principle for later program entry.

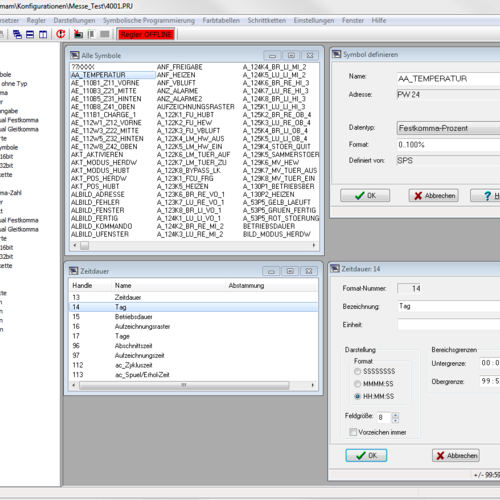

Format and symbol configuration

Formats and symbols can easily be created and configured in different categories. The formats are later assigned to symbols that can be used for block inputs/outputs. In addition to the normal configuration, formats can be derived from a primary format. The upper and lower limits as well as the display format are adopted.

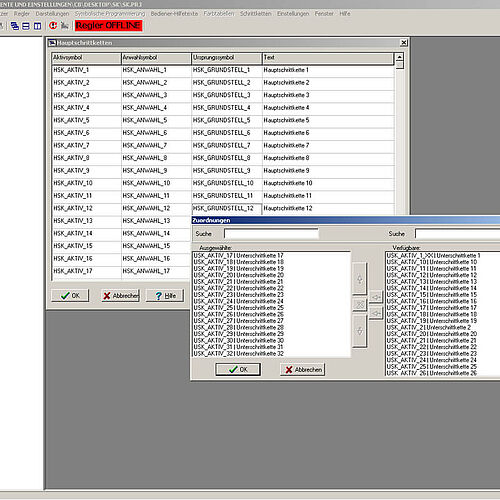

Sequence control

In some systems, sequences are used to control processes. In this part of the program, these sequences can be visualised in automatic mode and controlled manually in manual mode. The functions of the “Sequence” section of the program depend greatly on the system configuration, and cannot be described in a general fashion for all applications.

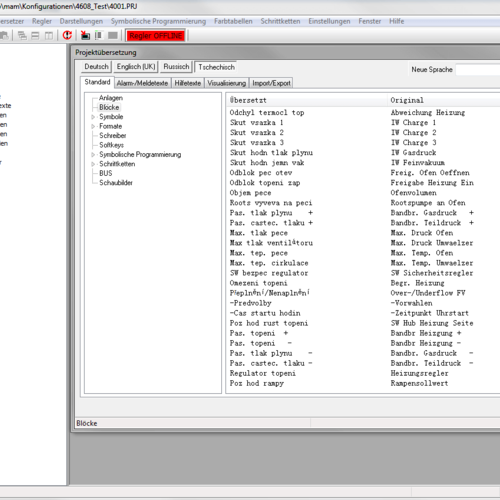

Multilingual capability

It is possible to translate a project into different languages for process controllers. These can be easily entered in the configuration program, then switched over in the control system during the run time. Complete Unicode support also makes it possible to use Asian character sets, for instance.

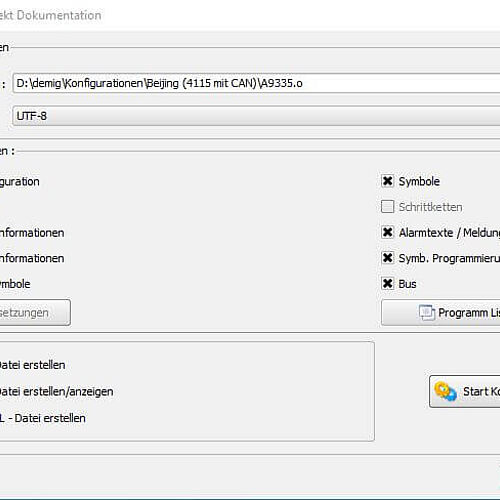

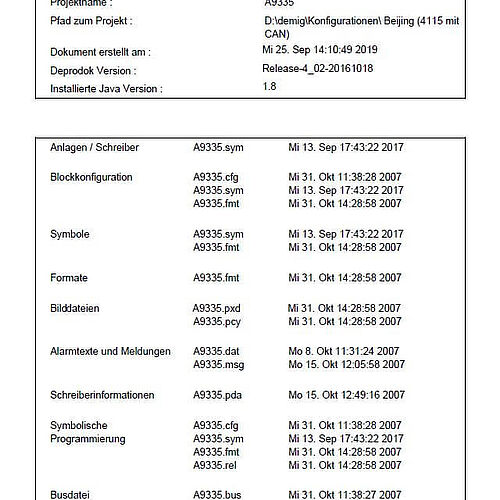

Compatibility with existing configurations

Existing control system configurations from the 4001/8 series can easily be transferred to later series. Existing visualisations can be converted automatically.

Communication and data transmission

A variety of communication options are available for communication between the configuration software and the process control system. The configuration software can communicate with the process controller via a serial interface (RS232/485/422) or network (TCP/IP).