The Demig DE-CP 342-01 series

Compatible & communicative

The process controllers of the DE-CP 34X-01 series are the perfect replacement controllers for our previous controller generations (from DE-PR 4008 series)! And the best thing about it?

Thanks to the integrated ECB bus, you can continue to use the existing control cabinet cut-outs for the DE-CP 342-01. Thanks to the innovative cooling concept, the operating temperature has been significantly reduced! In addition, the system is protected by an integrated UPS, which ensures a controlled shutdown in the event of a power failure.

The integrated ProfiBus module can be used to establish connections to ProfiBus-compatible hardware (master or slave possible)!

The user interface provides the user with a clear and intuitive visualization and operation of the processes on a 10-inch display with membrane keypad.

The system is driven by a processor that can also display complex visualizations smoothly.

The sequence programs are programmed using preconfigured process phases! The operator is automatically guided to the necessary input of variable data. Phase-dependent basic settings such as monitoring and safety functions are already stored in the system configuration.

Your advantages at a glance

Functional description

Operation

- Simple, intuitive menu-driven operation via a membrane keypad

- Process-oriented programming

- Language switching in the menu

- Individual configuration options for system manufacturers

Technology

- Convenient process visualization thanks to high-resolution colour displays

- Fast response times for control and image formation thanks to powerful processor

- Network-compatible via 2.5 GbE Ethernet

- Profibus (slave/master) connection possible with DE-CP XX2-01

- Profinet (slave/master) connection possible with DE-CP X24-01

- Remote communication for monitoring and maintenance

- Hardware watchdog for digital and analog outputs and for the overall system

- Panel mounting enclosure with IP65 front sealing and IP20 rear sealing

Data recording

- Recording of all process variables

- Integrated recorder functions

- Graphical and numerical data output

- Print functions

- Proof of quality within the framework of DIN ISO 9000

Regulation

- Multi-system control

- All standard control algorithms with parameter switching and setpoint correction

- Special functions (e.g. diffusion processes, F-value calculation)

Control system

- Integrated PLC (S5 © and S7 © compatible)

- Manual operating mode

- Step chain control

- Special functions (e.g. burner all-round control)

Visualization

- System diagram(s) with status display

- Alarm and notification display with help function

- Online process variable display numerically and as trend display

Technical data

Display and operation

- 10.4" TFT with membrane keypad

- Resolution 1024x768 pixels XGA resolution

- LED backlighting

- External USB mouse and/or keyboard can be connected

- Intuitive graphical user interface

Protection class

- Front IP65

- Rear IP20

- Operating ambient temperature 0...+45°C

EMV

- Emission EN 61000-6-4:2007 + A1:2011

- Interference immunity EN 61000-6-2:2005

System

- Intel® Dual Core 2 GHz

- 4GB DDR4 memory

- 40GB M.2 flash memory

- All data including programs, measurements and process status in Flash

- UPS for data integrity

- Multi-stage watchdogs, system status, voltage and temperature monitoring

- Real-time clock RTC, battery-buffered

- Integrated PLC, S5 © and S7 © compatible command set, max. PLC program length: 60,000 commands with time requirement for 1,000 bit commands of < 0.2 ms up to 256 timers, 1024 messages, 1024 alarms (optionally with switch-on delay)

Interfaces DE-CP XX2-01

- 2x Ethernet 2.5GbE with TSN support

- 1 COM DE9 DIN-RS232 (galvanically isolated)

- Further COM DE9 DIN-RS232/RS422/RS485 external Expandable

- 1x USB 3.1 Gen.2 Type C

- 2x USB 3.1 Gen.2 Type A

- 1x USB Demig IO

- Profibus DP (master or slave), RS-485, potential-free, D-Sub socket, 9-pin

- Various protocols integrated: e.g. ModBus TCP and RTU

Power supply DE-CP X4X-01

Main and I/O with separate power supply

- 24V DC ± 15% (Main)

- Power (main) typically 25W, max. 75W when SuperCap UPS is charging

- 24V DC ±15% (I/O)

- Power (I/O) typically 10-20W, max. 50W

- Potential separation GND/PE

- Buffering with SuperCap UPS

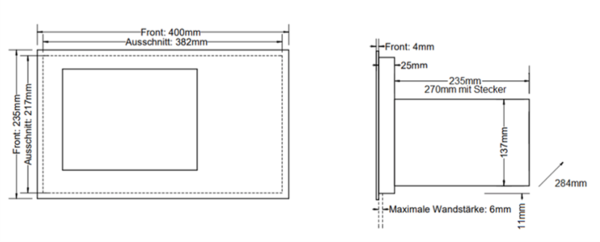

Dimensions and weight DE-CP 34X-01

- Aperture size 10" approx. 400x235x4mm

- Cut-out 10" 382x217mm or 284x137mm (adapter frame)

- Installation depth: approx. 235mm (270mm with plug)

- max. wall thickness 6mm

- Weight 10" approx. 6.0 kg

Accessories

- 8 Analog IN card

- 8 Analog OUT card

- 4 Analog IN / 2 Analog OUT Card

- 4 Analog IN/2 Analog OUT (switching output)

- 32 Digital IN card

- 32 Digital OUT card / 32 Digital IN-OUT card

- 24 Digital IN / 16 Digital OUT card

8 Analog IN card

Item number: 601613

8-fold analog input card

- All inputs are galvanically isolated from each other and from the system potential

- DC voltage, DC current measurement possible

- Inputs configurable: 0...100mV 0...500mV

- 0...2V 0...10V

- 0...20mA

- 0...400 Ω (2/3/4-wire technology)

- (error < 0.1% of the measuring range)

- Any combination of input circuitry

- min. Measuring time per channel 20mS

- Double reference junction measurement in the connector plug

Linearization is included in the scope of delivery for the following thermocouples.

- Cu-CuNi Type U ( -200 ... +600 °C)

- Fe-CuNi Type L ( -200 ... +900 °C)

- NiCr-CuNi Type E ( 0 ... +1000 °C)

- Ni-CrNi Type K ( -200 ... +1370 °C)

- PtRh-AuPdPt ( -100 ... +1300 °C)

- PtRh13-Pt Type R ( 0 ... +1740 °C)

- PtRh10-Pt Type S ( 0 ... +1760 °C)

- PtRh30-PtRh6 Type B ( 0 ... +1800 °C)

- WRe3-WRe25 ( 0 ... +2400 °C)

- WRe3-WRe26 ( 0 ... +2500 °C)

- NiCrSi-NiSi Type N ( -270 ... +1400 °C)

- Pt 100 ( -200 ... +800 °C)

8 Analog OUT Card

Item number: 601615

DA 8: 8-fold analog output card

- All outputs are galvanically isolated from the system potential

- Outputs: 0...10V load capacity >= 1kΩ

- 0(4)...20mA Load <= 1000 Ω

- Resolution 12 bit/0.025%

- Output rate dependent on configuration (min. every 100ms)

- Local watchdog function integrated

4 Analog IN / 2 Analog OUT Card

Item number: 601614

AD 4/DA 2: Analog combination card

Analog inputs (4):

- All inputs are galvanically isolated from each other and from the system potential

- DC voltage, DC current measurement possible

- Inputs configurable: 0...100mV 0...500mV

- 0...2V 0...10V

- 0...20mA

- 0...400 Ω (2/3/4-wire technology)

- (error < 0.1% of the measuring range)

- Any combination of input wiring via configuration software

- min. Measuring time per channel 20mS

- Cold junction measurement in the connector plug

Linearization is included in the scope of delivery for the following thermocouples:

- Cu-CuNi Type U ( -200 ... +600 °C)

- Fe-CuNi Type L ( -200 ... +900 °C)

- NiCr-CuNi Type E ( 0 ... +1000 °C)

- Ni-CrNi Type K ( -200 ... +1370 °C)

- PtRh-AuPdPt ( -100 ... +1300 °C)

- PtRh13-Pt Type R ( 0 ... +1740 °C)

- PtRh10-Pt Type S ( 0 ... +1760 °C)

- PtRh30-PtRh6 Type B ( 0 ... +1800 °C)

- WRe3-WRe25 ( 0 ... +2400 °C)

- WRe3-WRe26 ( 0 ... +2500 °C)

- NiCrSi-NiSi Type N ( -270 ... +1400 °C)

- Pt 100 ( -200 ... +800 °C)

Analog outputs (2):

- All outputs are galvanically isolated from the system potential

- Outputs: 0...10V load capacity >=1kΩ

- 0(4)...20mA Load <= 500 Ω

- Resolution 12 bit/ 0.025%

- Output rate dependent on configuration (min. every 100ms)

- Local watchdog function integrated

4 Analog IN / 2 Analog OUT card (switching output)

Item number: 601616

AD 4/DA 2: Analog combination card with limit value switch

Analog inputs (4):

- All inputs are galvanically isolated from each other and from the system potential

- DC voltage, DC current measurement possible

- Inputs configurable: 0...100mV 0...500mV

- 0...2V 0...10V

- 0...20mA

- 0...400 Ω (2/3/4-wire technology)

- (error < 0.1% of the measuring range)

- Any combination of input wiring via configuration software

- min. Measuring time per channel 20mS

- Cold junction measurement in the connector plug

Linearization is included in the scope of delivery for the following thermocouples:

- Cu-CuNi Type U ( -200 ... +600 °C)

Fe-CuNi Type L ( -200 ... +900 °C)

NiCr-CuNi Type E ( 0 ... +1000 °C)

Ni-CrNi Type K ( -200 ... +1370 °C)

PtRh-AuPdPt ( -100 ... +1300 °C)

PtRh13-Pt Type R ( 0 ... +1740 °C)

PtRh10-Pt Type S ( 0 ... +1760 °C)

PtRh30-PtRh6 Type B ( 0 ... +1800 °C)

WRe3-WRe25 ( 0 ... +2400 °C)

WRe3-WRe26 ( 0 ... +2500 °C)

NiCrSi-NiSi Type N ( -270 ... +1400 °C)

Pt 100 ( -200 ... +800 °C)

Analog outputs (2):

- All outputs are galvanically isolated from the system potential

- Outputs: 0...10V load capacity >=1kΩ

- 0(4)...20mA Load <= 500 Ω

- Resolution 12 bit/ 0.025%

- Output rate dependent on configuration (min. every 100ms)

- Local watchdog function integrated

Comparator inputs (2):

- The two inputs 0...10V are at the potential of the analog outputs and are compared internally.

- Potential-free relay output switches depending on the result of the comparator.

32 Digital IN card

Item number: 601611

IN 32: 32-fold digital input card

- All inputs are galvanically isolated from the system potential by optocouplers

- Input potentials 0 V...30V (DC) 15mA; logical 0 < 5V logical 1 > 15V

- Hardware debouncing of all inputs, min. signal length 200ms (other signal lengths possible on request)

32 Digital OUT card / 32 Digital IN-OUT card

Item number: 601612

OUT 32/IO 32: 32-fold digital input/output card

- all outputs can also be configured as inputs

- all outputs and inputs are galvanically isolated from the system potential by optocouplers

- Switching capacity per output max. 30V / max. 0.5A at max. 12W (ohmic load)

- external power supply of the output transistors 24V DC ± 15%

- Local watchdog function integrated

- Input potentials 0 V...30V (DC); logical 0 < 5V logical 1 > 15V

- Hardware debouncing of all inputs, signal length optionally 1.6 ms/0.14ms (longer or shorter signal length possible on request)

24 Digital IN / 16 Digital OUT card

Item number: 601608

IN 24/OUT 16: 24-fold IN/16-fold OUT card

- All inputs are galvanically isolated from the system potential by optocouplers

- Input potentials 0 V...30V (DC) 15mA; logical 0 < 5V logical 1 > 15V

- Hardware debouncing of all inputs, min. signal length 200ms (other signal lengths possible on request)

- All outputs can be loaded with 0.5A (all outputs can be switched on at the same time)

- Short-circuit resistance of all outputs

- Supply voltage 18VDC...36VDC

- Local watchdog function integrated

- Outputs are switched off when the supply voltage is < 16V

Additional modules

Online diffusion

(also activates the diffusion simulation in prosys/2)

Iron + carbon results in steel. At temperatures between 911°C and 1392°C, the lattice changes from body-centered cubic to face-centered cubic. Above this temperature, the lattice is again body-centered cubic, but the spacing is greater compared to temperatures below 911°C.

Carburization is used because mixing is not possible. Iron evaporates before carbon becomes liquid, hence the carburization process. The carbon diffuses into the still solid iron at high temperatures. This should happen without oxygen, so inert gases are used to prevent this.

Nitriding index calculation

This is a process for surface hardening of steel and other ferrous materials in which nitrogen is enriched in the metal surface.

Nitrocarburizing is a combination of nitriding and carburizing (i.e. carbon enrichment). The workpiece is exposed to ammonia in a furnace at temperatures of approx. 500°C to 600°C (in nitrocarburizing also with an additional gas containing carbon, e.g. carbon monoxide, carbon dioxide, propane, etc.). The ammonia or the additional gas partially splits on the surface of the workpiece; the resulting atomic nitrogen (or carbon) is embedded in the workpiece and forms a so-called hardening layer. The hydrogen released during nitriding escapes from the furnace together with the unsplit ammonia and is flared off.

Direct coupling Lambda sensor

A lambda sensor is a technical component for heating systems that measures the residual oxygen content of hot exhaust gases. This value can be used to create an optimum mixture of combustion air and flue gases in the combustion chamber, which leads to optimum combustion and reduces the formation of emissions.